Exit Shoe (ES)

For distributing material, the conveyors do not need any filter, no integrated Vacuum-Valve and no Check-Valve.

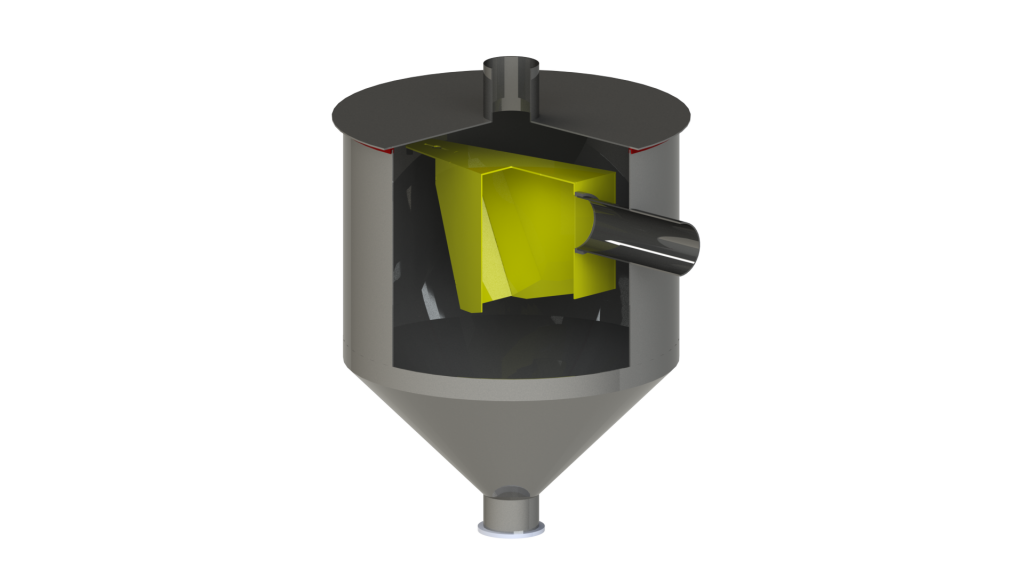

A simple Separator-Hopper will replace the Vacuum- and Pressure-Hopper Loaders. Therefor the Separator-Shoe is inside of the Separator-Hopper.

Function

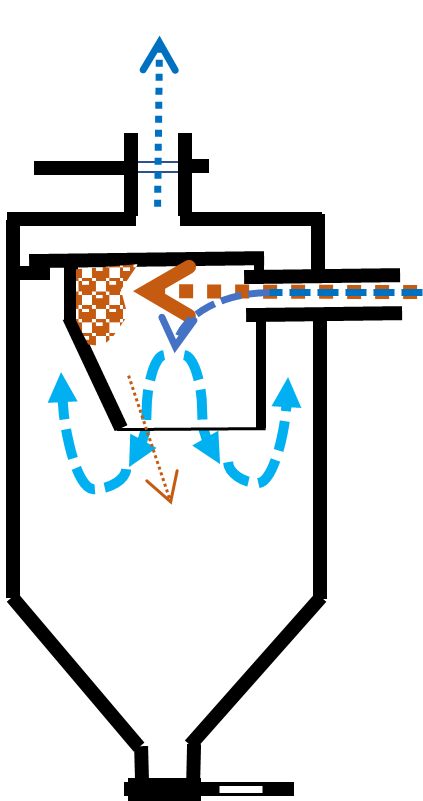

The Start of the conveying-cycle results from opening the valve (valve SASV) to the blower. The negative pressure in the separator and in the conveying-line builds up. When material enters the exit-shoe a material-buffer is formed immediately. This buffer annihilates the kinetic energy of the bulk material. The size of the material-buffer depends on the inlet velocity of the bulk storage.

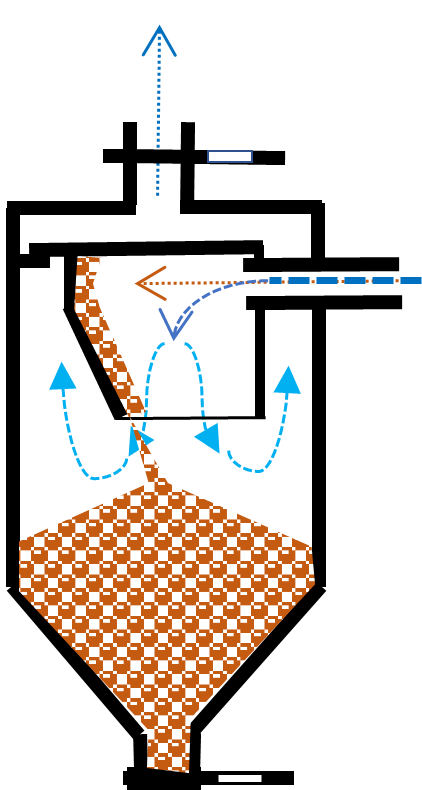

At the end of the conveying-cycle the valve to the blower is closed and the negative pressure disappears. The air velocity in the conveying-pipe becomes extremely low rather and the material stream is interrupted. The remaining material (material-buffer) in the separator falls down through gravity.

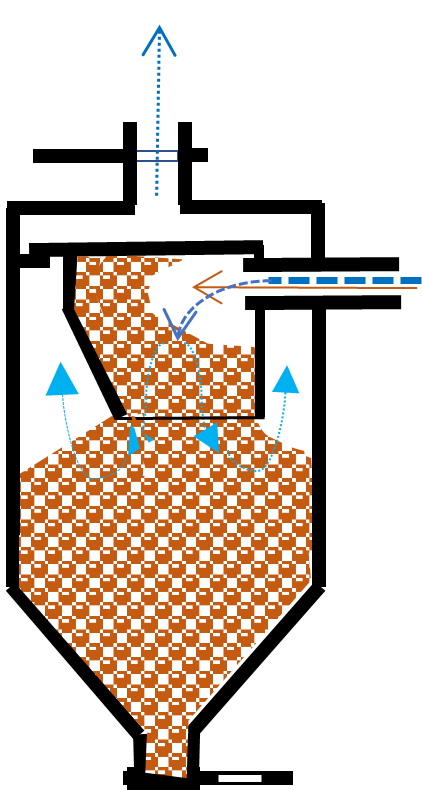

Usually the conveying-cycle is limited by the conveying-time. The filling-cycle can be finished through a fill-level-observation too. If an error prevents the conveying-cycle from finishing then the conveying-cycle stops auto-matically. A “plug” is formed in the lower part pf the separator, the air velocity is reduced and no material will be conveyed anymore.